Variable airflow monitoring and control to ensure efficient operation

-

Categories:

- Ductless Fume Hoods

- Operator Protection

Request Quote

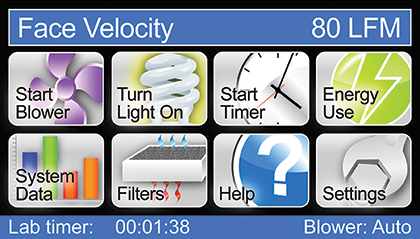

Application WorksheetAirClean Systems’ Endeavour Ductless Fume Hood provides the operator with user-friendly controls, superior construction materials and market-leading safety features needed for effective fume containment. These fume hoods can be placed virtually anywhere, without the need to connect to building infrastructure, giving you the flexibility expected from modern laboratory equipment.