Ensuring the Highest Quality in AirClean® Systems Bonded Carbon Filters

AirClean Systems ductless fume hoods, workstations, and enclosures are equipped with bonded carbon filters that are engineered to protect operators by effectively capturing and containing harmful chemical vapors. A two-step process is used to achieve the highest quality in filter performance. This consists of testing the activated carbon itself and then testing the fully manufactured filter against various chemical challenges to ensure optimum performance.

Sourcing activated carbon requires a test design that fairly and efficiently evaluates a particular carbon type from multiple vendors. AirClean Systems has developed a system that exposes multiple canisters containing equivalent carbon masses, at a particular humidity, to a controlled flow rate of a challenge chemical in the form of a pressurized gas. The canister effluent is monitored by a sensor for carbon breakthrough; that is, presence of the challenge chemical at part-per-billion (ppb) concentration, over a period of time. The test is performed multiple times to alleviate any experimental anomalies. All activated carbons used in AirClean Systems' filters have undergone this rigorous testing.

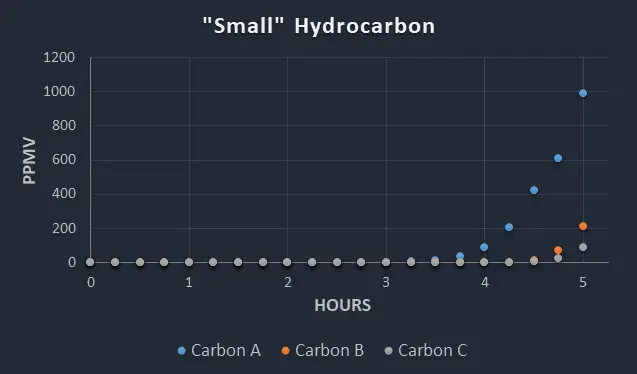

Challenge chemicals have been selected based on hydrocarbon molecular size (e.g., "small" and "large"), organic functional groups (e.g., aldehyde), and as acids and bases. Figure 1 shows test results for the "small" hydrocarbon. There is clearly a differentiation in performance. Carbon A experienced breakthrough at about 1 hour prior to Carbon B and Carbon C. As small molecules are generally less tightly held within the activated carbon's micropores by van der Waals forces, only Carbons B and C are qualified for use in filter manufacturing. The same methodology applies to the other challenge chemicals. The carbons ultimately used for our filters are selected based on superior or equivalent performance.

Chart 1.

Once the activated carbon is sourced, filters are manufactured and tested in accordance with SEFA 9 criteria. Specifically, AirClean Systems advanced, high-capacity Siliconazyne™ filters were qualified under these guidelines and monitored by an outside certifier. Current filter testing for products that do not use Siliconazyne filters, however, employs comparable methodologies to ensure high standards in filter testing without outside certification. Comparably, chemicals are flash-evaporated in an enclosure equipped with the candidate filter and filter breakthrough is closely monitored.

This two-step methodology permits activated carbon testing for quality assurance purposes as well as for evaluating new carbon products as the need arises. Filter testing ensures high quality standards are met, standards that allow operators to safely conduct chemical operations in AirClean Systems products equipped with proven AirClean Systems filters, in accordance with the Application Worksheet parameters. When you use an AirClean Systems product, you can rest easy knowing that the filters have been thoroughly tested to ensure the highest level of performance.