Next generation ductless fume hood technology

-

Categories:

- Ductless Fume Hoods

- Operator Protection

Request Quote

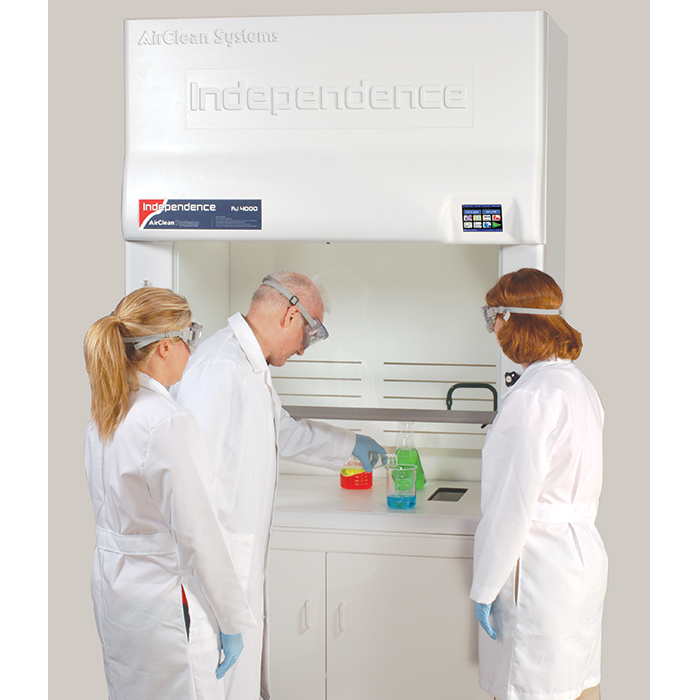

Application WorksheetAs research and laboratories evolve, AirClean® Systems continues to innovate with sophisticated, efficient fume containment solutions. Independence™ is the culmination of two decades of research and development in airflow design, gas-phase filtration, fume detection and fume hood control technologies. The ductless fume hood has now come of age.

Independence provides real-time PPM measurements for filter saturation, an on-board application validation system, class-leading airflow control and a host of innovative features unique to the ductless fume hood marketplace. Never before has a fume hood been able to offer this level of safety and performance.

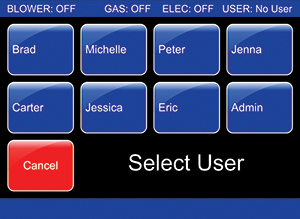

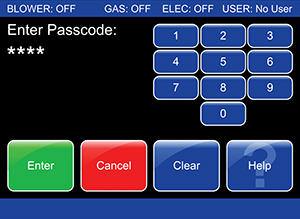

Multi-Level User Access

Administrator-defined access for up to eight users within three levels.

- Level 1 - Restricted Access- Does not have access to setup screens, and can be restricted from accessing the following features:

- Burning gas

- Electrical outlets

- Fluorescent light

- Blower on/off and mode change

- Lab countdown timer

- Shutdown

Eight distinct logins with varying levels of access.

Each login has a unique passcode.

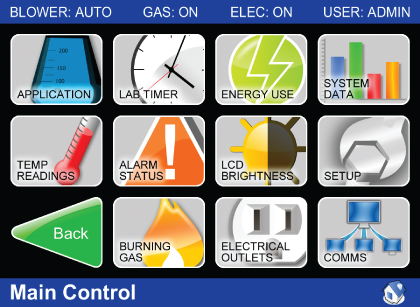

- Level 2 - Standard Access - Can utilize all functionality that is not behind the ″Setup″ quick key. This includes all controls needed to use the hood on a day-to-day basis.

- Level 3 - Administrator Access - Unrestricted access to all features and setup screens within AirSafe™ TOUCH. In addition to all ″Quick Key″ functionality on the main control screens, an administrator can enable/disable most safety alarms, set alarm values, modify the approved chemical application, replace filters and perform other administrative functions.

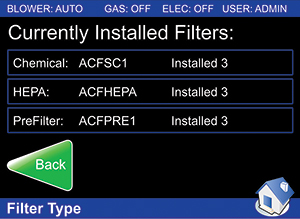

- Application and Filter Input

- During factory QA/QC, the user's approved chemical application and installed filter type are programmed into Independence™.

- In the event chemicals are to be added or removed at a later date, an administrator-level user can make this change via AirSafe™ TOUCH. Updating filter information is equally as simple.

- The approved application and installed filter lists are available to any user directly from the ″Main Controls″ screen.

Currently installed filters and approved chemical application are easily available.

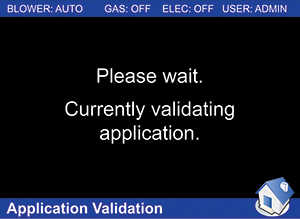

Real-time application validation at your fingertips.

- Application/Filter/Sensor Confirmation

- FilterStat™ actively validates the chemical application against the installed filtration and gas detection package.

- AirSafe™ TOUCH will confirm that all chemicals, filters and gas sensors are compatible. If they are not, the system will require the user to install correct filters, modify the application or consult an AirClean® Systems application specialist for further review.

- Filtration Monitoring

- Interfaces with the exclusive TriAnalyze™ 3x3 multi-method gas detection system.

- Automatically calibrates the PID, monitoring for a target application chemical and setting alarm values based on the chemical's TLV.

- Real-time Interfilter™ chemical saturation levels are monitored and displayed in parts-per-million.

- Three Sensors

- PID Gas Analyzer - Used in conjunction with the extensive onboard chemical database, the PID gas analyzer provides real-time readout of saturation levels in exact parts-per-million.

- Metal Oxide Array - This industry-standard sensor constantly monitors for a wide range of hydrocarbons found in common applications

- Acid Array - Real-time acid detection is provided via Independence's custom-tailored electrochemical cell, capable of sensing low-ppm acid gases.

- Three Samples

- Interfilter™ Sampling Port - This unique sampling port allows each sensor to monitor air within the filter, giving users the ability to be notified of filter saturation before breakthrough occurs.

- Filter Exhaust Sampling - Located in the exhaust air stream, this sampling port confirms filter saturation and alerts the user to change filters.

- Room Air Sampling - As an added safety measure, room air saturation measurements are taken. A separate target chemical can be selected to monitor for chemicals that may be present in the room but not used in the hood's application.

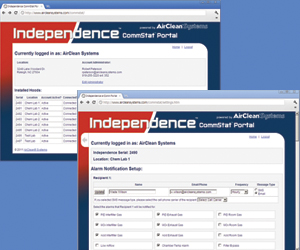

- Web Portal

- Logging into the web portal provides the user with a "snapshot" view of each Independence™ hood in the account showing the serial number, hood location, status, and current alarm condition.

- The chemical application and alarm notification history for each hood may also be reviewed.

- For each Independence™ hood, up to five alarm notification recipients can be enabled. Each recipient can custom-tailor which real-time alarm notifications they wish to receive.

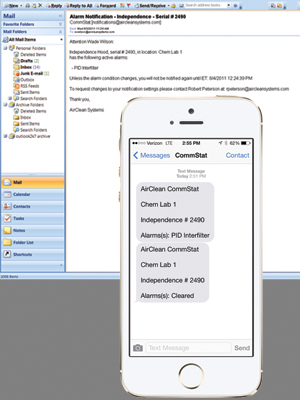

- Instant Notification

- Real-time alarm notifications can be sent as either an email message or SMS text message. Each notification includes the Independence™ serial number, physical location and which alarms are currently active.

- In addition to alerting recipients of their selected alarms, CommStat™ will also notify the recipient when the alarm condition has cleared.

Instant notification is available via SMS text message.

Web portal is provided for alarm notification setup.

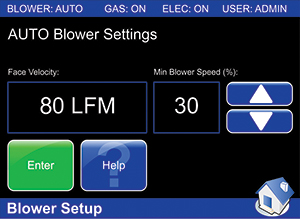

- Automatic Blower Mode - Allows user to set desired face velocity from 30 to 150 linear feet per minute (LFM) or .15 to .75 meters per second (m/s). Blowers will automatically accelerate/decelerate to maintain face velocity based on input from the proprietary AirSafe™ TOUCH airflow sensor.

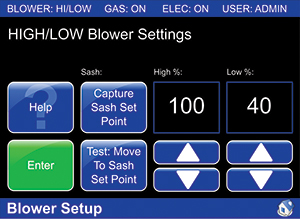

- High/Low Blower Mode - Allows user to store a sash "mid point" and both a "high" and "low" blower speed. When the sash is raised above the mid point, the blowers will run at the high speed. Conversely, when the sash is lowered below the mid point, the blowers will run at the low speed.

- Manual Blower Mode - Allows user to set a percentage of maximum blower speed. Regardless of sash position or operator interaction, the blowers will maintain their pre-set speed.

Auto Blower Mode

High⁄Low Blower Mode

The advanced airflow sensor allows hood administrators to set the minimum and maximum face velocity. Should the face velocity move out of this range, the user is notified with an audible and visible alarm.

Temperature sensors are incorporated in both the chamber and filtration column, alerting the user both audibly and visibly in the event of a significant increase in temperature.

The sliding safety glass sash is monitored by a sash reader, providing the AirSafe™ TOUCH controller with real-time sash position information. An administrator can set high and/or low sash alarm points that will notify the user if the sash is out of range.

A timed control mode allows the services to run for a pre-set time, then automatically turn off once the timer has expired. Additionally, if blowers are not on, burning gas is disabled. Both features help prevent gas build-up in the event that a manual fixture is left open.

- Ductless design for significantly reduced installation costs

- Polypropylene construction eliminates potential for rust

- High-performance curved air entry

- Removable flame-retardant base positioned above integral spill basin

- AirZone™ baffling promotes even airflow pattern and provides exceptional capture capability

- Dual wall construction for service and fixture placement

- Motorized safety glass sash

- Hinged front panel for simple filter access and replacement

- Designed, tested and manufactured in the USA