The look and feel of a traditional fume hood, without the associated installation or energy costs

-

Categories:

- Ductless Fume Hoods

- Operator Protection

Request Quote

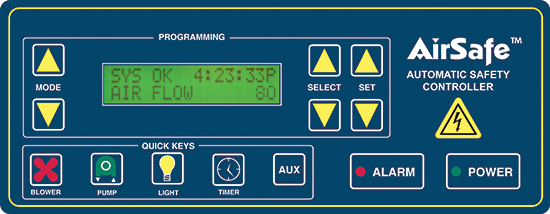

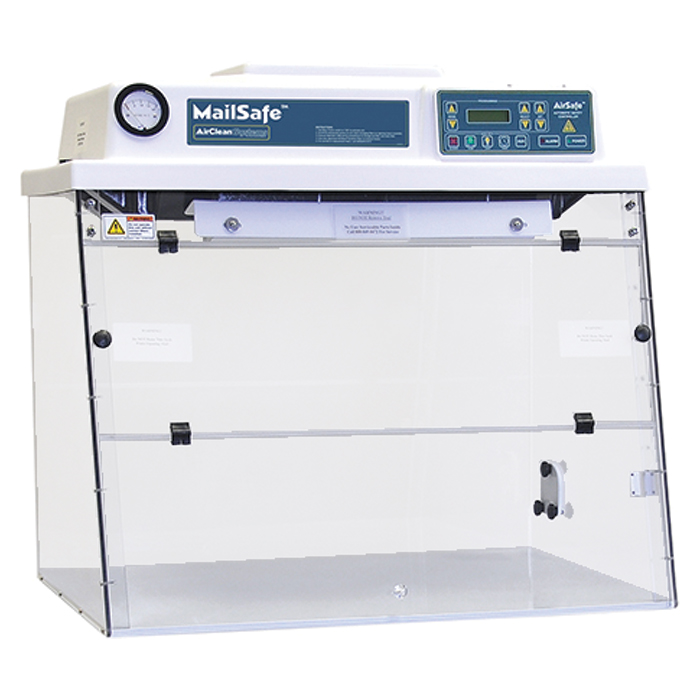

Application WorksheetAirClean® Systems polypropylene ductless fume hoods with vertical sliding sash are similar to traditional exhaust fume hoods, yet do not require connection to costly ductwork or HVAC systems. Operators familiar with exhaust hoods feel at home thanks to the vertical sliding safety glass sash, dual wall construction, and optional front-mounted fixtures. In addition to these time-tested features, the AirSafe automatic safety controller provides constant airflow monitoring, automatically maintaining the operator-specified face velocity as the sash is raised or lowered.