Innovative design provides both operator and process protection

-

Categories:

- Biological Safety Cabinets

- Application Solutions

Request Quote

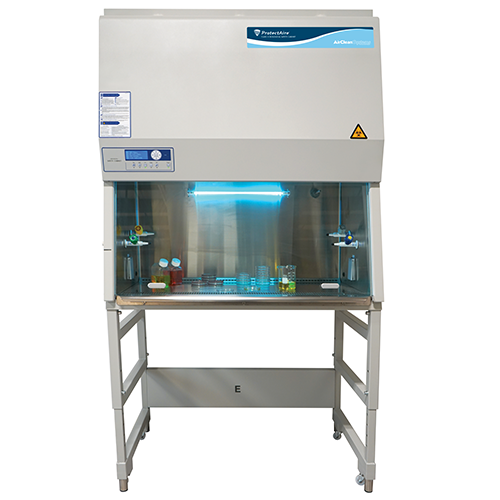

The AirClean Systems ProtectAire BSC has an innovative design equipped with dual DC centrifugal fans to create an ultra low-noise Class II Type A2 biological safety cabinet. ProtectAire cabinets are ideal for applications that require operator protection from potentially harmful biological samples and process protection to minimize potential sample contamination from the environment. This is achieved by recirculating 70% of the cabinet air through ULPA filters while exhausting 30% of the air through ULPA filtration. Combining unidirectional downflow ULPA-filtered air with high-velocity inflow room air creates an active air barrier at the front of the chamber. This barrier separates the laboratory from the work area and maintains a constant inflow speed to prevent environmental contaminants from entering the work area or potentially harmful contaminants from escaping. The operational voltage of ProtectAire Class II BSC is 100-230V 50/60 hertz, making it a universal solution for a wide range of countries and regions around the world.

The ProtectAire working chamber is fabricated from stainless steel and has an ergonomic platform armrest for the technician's comfort. The work surface is manufactured with 304 stainless steel without any fixed screws that, in other designs, would allow for the accumulation of contaminants. The units come standard with two waterproof electrical outlets and an adjustable stand with universal locking casters. The casters and adjustable stand are cold rolled steel with corrosion-resistant epoxy resin powder paint.

The ProtectAire Class II A2 BSC chamber is controlled by the automatic safety controller. The controller functions include abnormal operation condition alarms, filter and UV lamp service life warnings, one-touch UV lamp timer function, running status, and interlock technology. The controller also receives real-time inputs from the hot-ball anemometer that monitors airflow in the working and exhaust areas of the cabinet. The anemometer then compares this with the standard airflow required to operate the chamber correctly and adjusts the blowers to maintain the constant airflow. Audible and visible alarms indicate any performance issues that require the technician’s attention or that could compromise either the application or the safety of the operator.