Perfect for enclosing laboratory apparatus

Featuring theRequest Quote

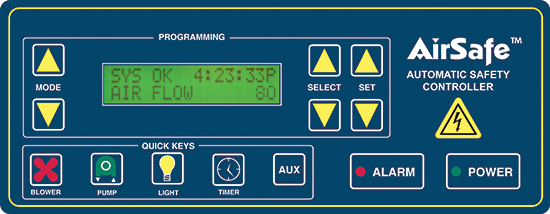

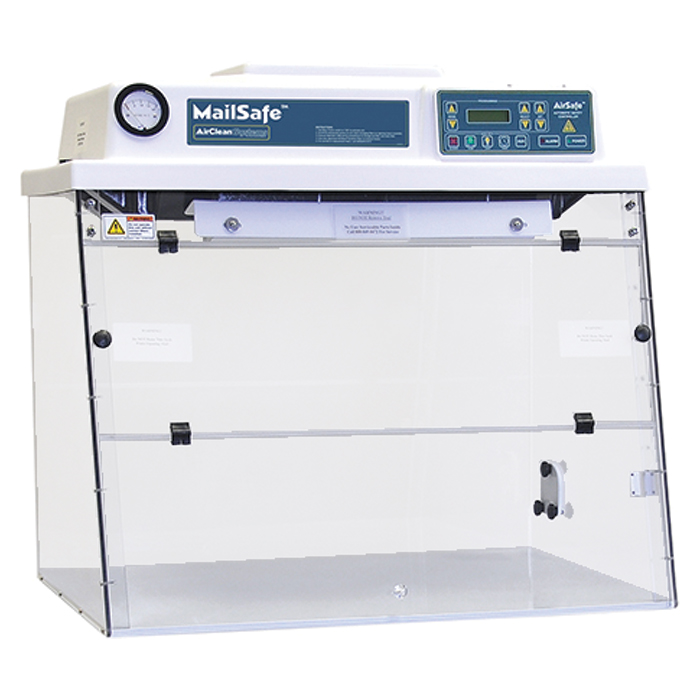

Application WorksheetAirClean® Systems rotary evaporator enclosures are engineered specifically for enclosing rotary evaporators, chromatography equipment and robotic equipment while allowing unrestricted access for operator interaction. The clear polycarbonate shell and horizontal sliding doors provide visibility and ergonomic access for monitoring the enclosed equipment. The AirSafe automatic safety controller maintains airflow and constantly monitors filter condition. At only 24 inches deep and 38 inches wide, this enclosure takes up very little counter space.