Safe Package Receiving Practice

There's a knock at the door, but you are not expecting anyone today. Puzzled by the mysterious knock, you open the front door to see a brown cardboard box on your doorstep. Your favorite coffee beans were delivered a day early, so you grab the box and a pair of scissors and ferociously cut open the box. The strong, sweet aroma of dark roast espresso beans fills the air, but the smell is much stronger than usual. As you grab one of the bags, espresso beans pour out onto the kitchen floor. You quickly stop the hemorrhaging from the broken bag using tape, but the damage is done. Half of your delicious beans will never make it into your coffee pot. Even after cleaning up the mess, the heavenly espresso smell lingers, reminding you of the disappointing delivery. Thankfully, it was just a coffee bean shipment. In the world of hazardous chemicals, this situation could have been far worse.

Packages: An Overlooked Workplace Hazard

Receiving packages is an often-overlooked potential workplace hazard. On any given day, a busy lab, manufacturer, or company may receive dozens of packages of hazardous chemicals. Most of these packages arrive intact, but handling and transport could cause the containers to break or leak, exposing recipients to dangerous substances. However, United States Department of Transportation regulations1 require that packaging used for shipping hazardous chemicals must be able to contain leaks (49 CFR, Part 178). Therefore, some leaks may go unnoticed if the items do not breach their outer packaging. The recipient may open the package and find the liquid or powdered chemical mixed with the adsorbent packaging, which may release hazardous vapors.

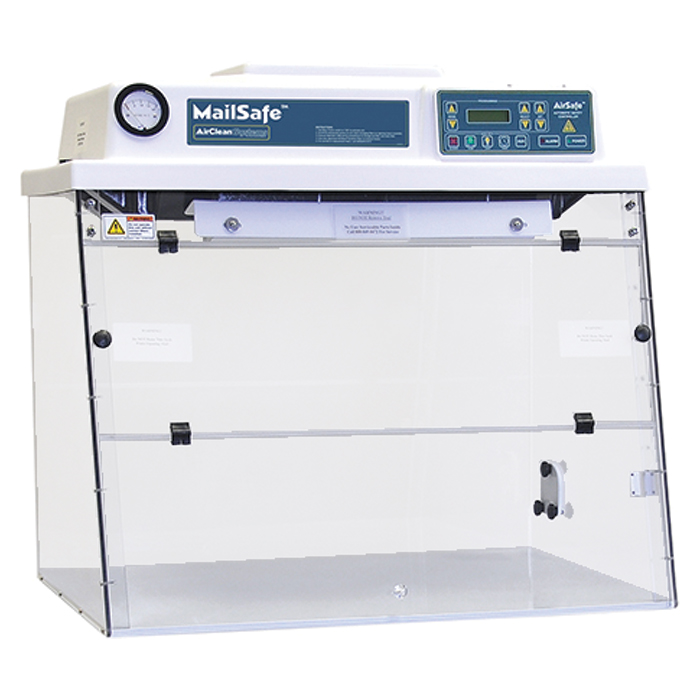

Opening packages can present a safety risk when hazardous chemicals are accidentally damaged during transit or when packages are intentionally used to conceal dangerous substances. In many countries, including the U.S., domestic and international mail is screened for pests, stolen artifacts, counterfeit goods, biological agents, and illicit substances2. Packages suspected to contain any of these items must be opened and physically inspected through sampling and testing to identify their contents. Exposure to even small amounts of some substances, such as fentanyl, can be fatal. Therefore, individuals tasked with inspecting suspicious packages must take precautions as this increases their risk of exposure to potentially hazardous materials. Opening packages in the appropriate ductless fume hood or workstation can protect recipients from vapors and particulates to avoid injury or illness.

Ductless Enclosures Can Protect Individuals From Hazardous Chemical Exposure

Packages known or suspected to contain hazardous substances should be opened and inspected in an appropriate ductless fume hood or workstation to avoid exposure. The ductless fume hood or workstation should provide operator protection by pulling air from near the operator, across the workspace, and to the enclosure's top and/or back. This air should then be filtered through the appropriate filter(s) before being exhausted into the room or environment. Packages suspected to contain illicit substances, such as fentanyl, should be opened in a ductless fume hood fitted with a high-efficiency particulate air (HEPA) filter and an activated carbon filter. Ductless workstations containing a HEPA filter can be used to protect against suspected biological agents. In contrast, packages of known hazardous chemicals can be opened in a fume hood or chemical ductless workstation fitted with an activated carbon filter. Users must be vigilant in choosing the correct filters and enclosures to protect their specific applications and likely exposures. Though your workplace will never be filled with the sweet aromas of a broken coffee bag, it's a small price to pay for safety.

References

- Federal Motor Carrier Safety Administration. How to Comply with Federal Hazardous Materials Regulations. July 2022. Accessed from: https://www.fmcsa.dot.gov/regulations/hazardous-materials/how-comply-federal-hazardous-materials-regulations

- U.S. Department of Homeland Security. Package Screening Systems. November 2010. Accessed from: https://www.dhs.gov/publication/package-screening-systems