Understanding Fuel Analysis

Society is powered by multiple energy sources, including fossil fuels, wind, and solar power. Over one-quarter of all energy consumed in the United States in 2022 was used for transportation, making it the second largest energy use sector, just behind electric power generation with 38% of all energy1. Petroleum-based fuels accounted for about 90% of energy consumption in the transportation sector1 despite recent interests in transitioning to electric and hydrogen-powered cars, buses, and trains. Refineries transform crude oil into gasoline, diesel, marine, aviation, and jet fuels to produce these petroleum-based fuels. Each of these meets the unique requirements of the engines that utilize them due to their complex blend of hydrocarbons and other organic chemicals.

Common Petroleum-based Fuels

Gasoline is a mixture of hydrocarbons, including alkanes, alkenes, isoalkanes, cycloalkanes, and aromatics (e.g., 0.5-2.5% benzene), typically comprising about 4-12 carbon atoms. The resulting gasoline may contain about 150 different compounds with various additives providing mixture stability and function as octane enhancers, antioxidants, lubricants, detergents, anticorrosion agents, and chelating agents. As a substitute for toxic aromatic compounds, most gasoline today is blended with biofuel and ethanol. According to the Environmental Protection Agency (EPA), the addition of ethanol reduced the overall toxic aromatic content of gasoline from about 25% in 2005 to 20% in 20162.

Diesel contains about 75% C10 – C15 hydrocarbons and 25% aromatic compounds. Diesel engines compress air and fuel to produce heat for combustion to drive the piston, whereas spark plugs ignite gasoline to provide combustion. Legislation to limit sulfur content in diesel fuels has resulted in research on additives that can provide sulfur’s natural lubricity for mechanical parts.

Jet A fuel, used in aircraft equipped with turbine engines, is a form of highly refined kerosene containing C9 – C16 hydrocarbons, cyclic hydrocarbons, and aromatics. It is designed to operate at low temperatures found at high altitudes (-47 °C) with heat exchanger assistance, whereas traditional gasoline would freeze. Aviation gas, or avgas, contains gasoline mixed with tetraethyl lead as an octane enhancer and is used by light aircraft powered by piston engines.

Marine gas oil, used on larger marine vessels, is obtained as blended distillate fractions with a smaller portion of heavy fuel oil (HFO) and lower viscosity compared to marine diesel fuel. HFO is highly viscous and contains high amounts of sulfur. Low-sulfur content regulations passed in 2020 resulted in the switch from high HFO-containing marine diesel fuel to marine gas oil for less sulfur.

Analyzing Fuel Types and Properties

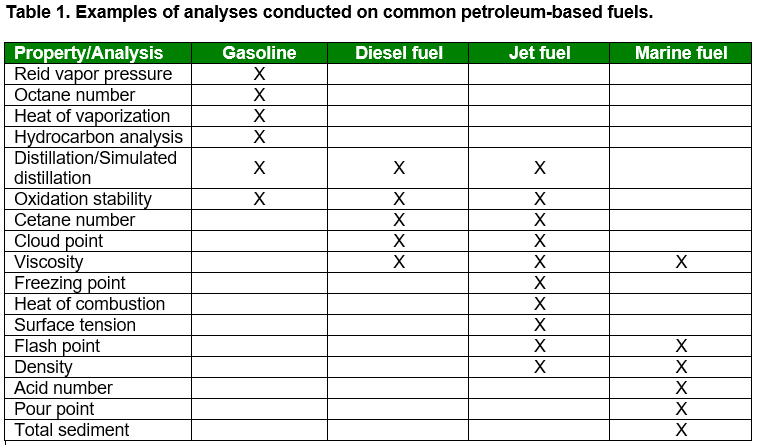

The fuels produced from crude oil refinement are subject to various technical, industry, and environmental standards; necessitating analysis of fuel composition and physical properties to ensure standard compliance as well as fuel consistency and performance. Examples of common fuel analyses are summarized in Table 1. However, this list is far from all-inclusive. Fuels can contain hundreds to thousands of compounds for analysis. Therefore, the types and number of analyses that must be completed on a fuel sample varies by fuel type and intended use.

Table 1 summarizes common fuel analyses but is not limited to these examples.

Ductless Fume Hoods Provide Operator Protection

Operators conducting fuel analysis may be exposed to high amounts of harmful fuel vapors on a consistent basis without proper engineering protections. Fuels may also contain known carcinogenic compounds, such as the common fuel additive benzene. All petroleum-based fuels and their vapors are highly flammable and pose a fire risk if the vapors are not contained. Activated carbon filtration in ductless enclosures can substantially contain fuel hydrocarbons and their additives. Fuel analysis should be conducted in a fume hood with a horizontal laminar flow that pulls air from under the sash near the operator and across the workspace. The contaminated air from the workspace is then pulled to the back and top of the hood, where it is filtered to remove harmful vapors and particulates prior to exhaust. Personal protective equipment (PPE) must always be worn, along with working in a ductless fume hood, to protect from harmful fuel vapors.

AirClean® Systems ductless enclosures suitable for these applications are equipped with innovative technologies that enhance operator protection. All units have airflow sensors to monitor the user-defined face velocity and will audibly alert the operator if it’s not maintained. This ensures that harmful fumes are consistently drawn away from the operator into the filtration system. As humidity and temperatures increase, the capacity for activated carbon to contain volatile chemicals decreases. Therefore, the humidity and temperature sensors found on the Endeavor™ Ductless Fume Hood provide data on the laboratory environment and alarm if pre-set values are exceeded. Carbon filter breakthrough is monitored in all AirClean Systems ductless hoods and workstations by a metal oxide sensor that is highly sensitive to the types of chemicals commonly found in petroleum products (aliphatic and aromatic hydrocarbons, alcohols, ethers, aldehydes, ketones, carboxylic acids, ammonia and amines, hydrogen sulfide, sulfides, and mercaptans.)

A ducted hood could also be used for fuel analysis, but it requires ductwork installation and maintenance and the cost incurred with continuous venting of room air to the outside. Ductless enclosures provide value in the economics of on-demand use, lowering carbon emissions and their portability as long as they remain in proximity to electrical outlets. As we advance, fuel research will likely be directed toward reducing carbon dioxide emissions. Development projects in biodiesels derived from various plants and hydrogen fuel cell technologies remain ongoing. Activated carbon filtration in ductless enclosures will continue to protect operators from solvents used in these processes to promote safety and regulatory compliance.

References

1. https://www.eia.gov/energyexplained/use-of-energy/transportation.php

2. https://www.eesi.org/articles/view/ethanol-can-help-reduce-toxic-gasoline-aromatics